Courtesy of Hermes

The enormity of the challenge to save Planet Earth can feel very overwhelming. The troubling question I keep coming back too, is where to start? Effecting change requires a fundamental shift in human behaviour which is an enormous challenge for a species which is inherently selfish. I’m not going to decry COP26, which appears to be the only concerted international attempt to encourage dialogue and concession between nations about our collective future. But you only have to look at the appalling decision of the UK government, in cutting our international aid budget by 0.2% of national income, to realise that the road ahead is likely to be destructively long and far from certain.

Design is inherently optimistic, that is its power

A quote from William McDonough, an American Architect and author which I spotted on Mykkö’s Instagram feed (more later). Time to take solace in the groundbreaking work of some scientists, designers and artists.

Hard wood

Scientists at the University of Maryland have discovered a way to make wood 12 times stronger and 3 times denser than its native form. It means that the treated wood is as strong as steel but 6 times lighter. A potential competitor to steel and titanium alloys, it is comparable to carbon fibre but a lot less expensive to manufacture.

To create this new super wood, natural wood is boiled in a mix of sodium hydroxide and sulphite, similar to creating paper from wood pulp. This partially removes two polymers, lignin and hemicellulose making the rigid cell walls of the wood more porous. After further heating and compression, new hydrogen bonds form between cellulose molecules, resulting in an altogether tougher material.

Inventwood, a tech start-up of material scientists from the university are now looking to explore commercial opportunities for MettleWood, their trademarked super wood, described as the strongest and toughest material to ever grow on trees. The beauty of their discovery, is the opportunity to replace slower growing hard woods like teak and mahogany in furniture making, for fast growing soft woods like pine and balsa. But it goes much further. A relatively inexpensive material with new super powers, grown to order before simple chemical processing could be used for vehicle components, building materials, shipping containers or perhaps a new type of flying machine which takes advantage of its inherent strength, lightness and cost.

The miracle called mycelium

The biggest mammal in the world might be a Blue Whale, but the biggest organism is a fungus, to be precise, a honey fungus, found in the Blue Mountains of Oregon. Its size has nothing to do with anything that grows above ground but the network of tiny, white threads on and underneath the forest floor. The mycelium of this particular fungus fuse into a single organism the size of 1,665 football pitches, 2,400 acres.

Mycelium is the vegetative part of a fungus which grows outwards from the stationary bit we see above ground, in search of water and nutrients such as nitrogen, carbon and potassium.

Buttery leather

Mycelium can also be grown and processed to look and feel like calfskin leather. This natural disruptor could immediately reduce our dependence on cattle, especially if the fall in red meat consumption continues, 13.7% down in the last decade in the UK. It also opens up new opportunities in the tanning industry. There has been a trend to use free of chromium (FOC) leather in cars and furniture, replaced by vegetable tanning for sometime. This has not been adopted by the clothes industry because vegetable tanning agents aren’t as readily available.

Born in the USA

When you look for mycelium leather manufacturers, the US has two notable start-ups with slick web sites and lumpy funding. Bolt Threads with Mylo trademarked leather and MycoWorks with Reishi, their brand name for fine mycelium leather.

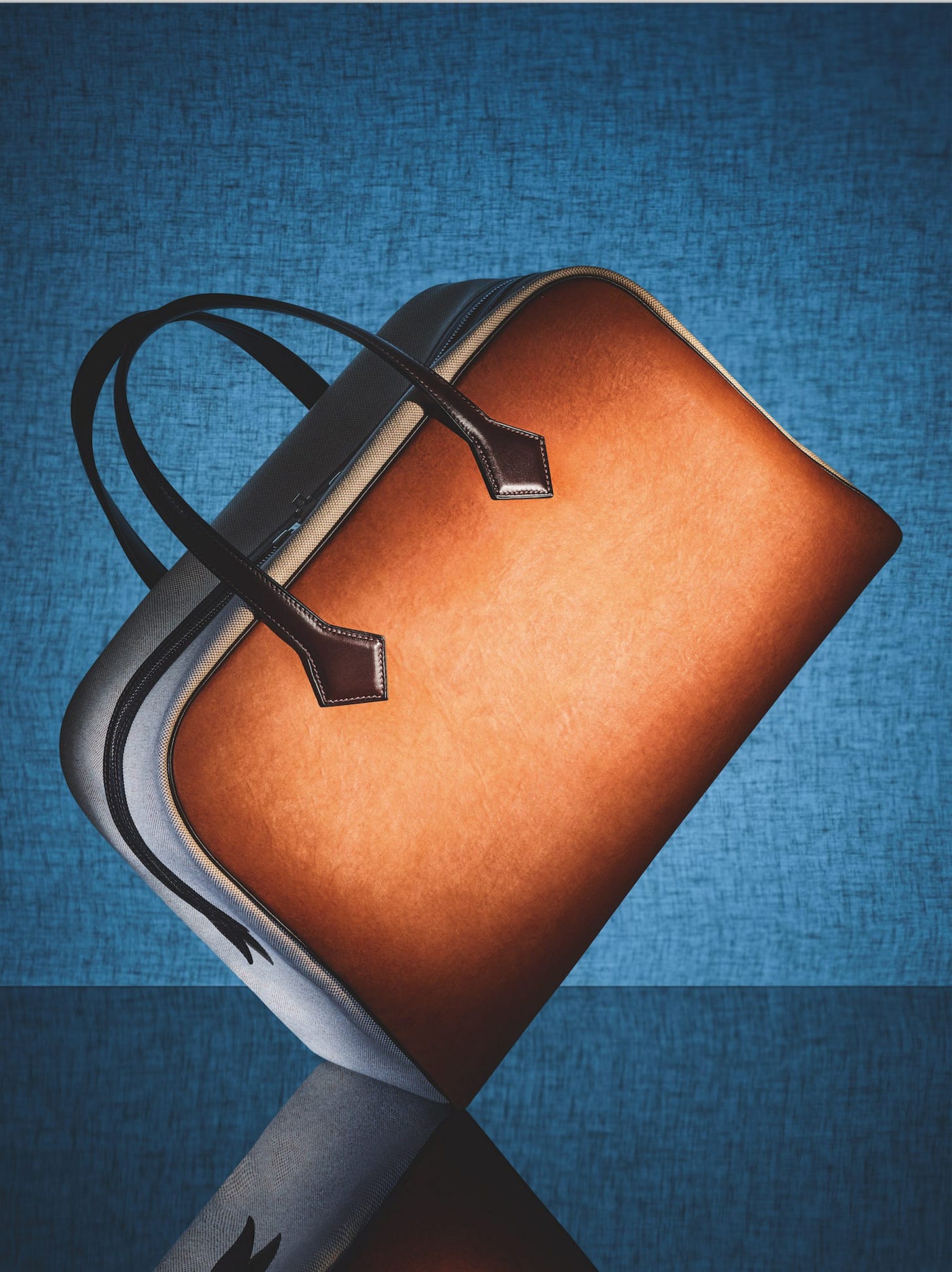

MycoWorks have a longer and more interesting story. Philip Ross, a San Francisco artist has been cultivating mycelium for art and design since the 1990’s. His journey has now been commercially vindicated by Hermes, who are using their mycelium leather in their Victoria Bag In Sylvania.

Their big breakthrough came with their closed tray system to grow the mycelium with a consistent strength, thickness and breathability. The system has also been scaled for volume production and the trays can be custom-shaped to grow the material to specific dimensions so there is no waste. Think about the opportunity of growing leather shoes to size close to an existing supply chain. Amazing.

Not to be outdone, Bolt Threads announced that they were already collaborating with Stella McCartney, although no products have been announced yet.

Made in the UK

Given my pledge to only purchase clothes and footwear from the UK, I was hoping that a UK company was hot on the heels of the two US manufacturers. I could be in luck.

Mykkö is billed as a UK research and development project funded by government grants and awards. Their focus is also a mycelium based luxury leather, circular by design (recycling built-in) and a low carbon footprint. Aurélie Fontan, a French born fashion designer who studied at Edinburgh College of Art is one of the two founders. She was kind enough to provide more insight into some of the challenges they face and the different approach they’ve taken.

Unlike the US companies, Mykkö focus on localised collaboration and not foreign supply chains. They go shopping for their mycelium species in local forests. The process can start with as little as one cell of mycelium.

Stella might be spoken for but they currently target small to medium sized independents with collaborations in theatre, skincare, jewellery as well as luxury fashion. They want their fabric to remain 100% compostable, unlike Bolt Threads’, Mylo, which contains a thin plastic laminate to sustain fabric performance.

Greenwashing

This smacks of greenwashing which the vegan leather market has been guilty of in the past. Primark launched their vegan leather range called PU in 2020. It’s made from polyurethane, which is not an eco-friendly breakthrough, but a type of plastic which has been used since the 1950s in the soles of trainers. As Fontan says,

“We cannot understand why innovation using nature needs to always be partnered with plastic; there are smarter ways to do this.”

Tanning and smell

They don’t bother with processes which were designed for leather like their competitors and instead focus on bio-based coatings designed with mycelium in mind. They’ve achieved good results with black, red and brown colours using entirely natural pigments and solutions.

Prior to being coated there is a faint mushroom odour, a sign of its natural origin. Afterwards, no smell at all. But given that the traditional smell of leather comes from a vegetable tanning process dating back 5,000 years, using oak and spruce bark originally, I expect high fashion can still demand its tannin fix, especially if it means that mycelium leather is adopted more quickly.